Home >> Products >> Steam trap

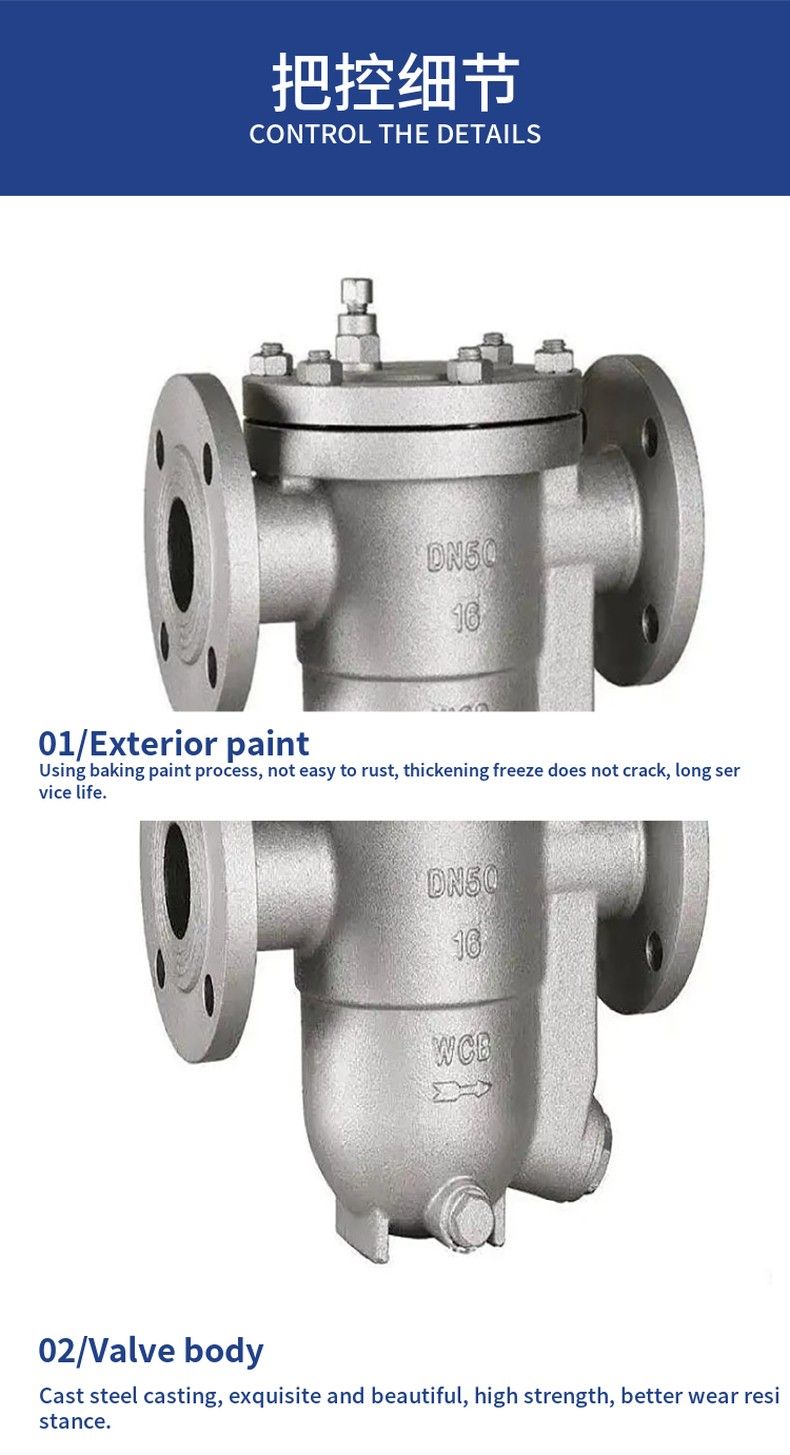

Free float type steam trap is one of the most advanced steam trap in China. The product technical quality and manufacturing process have reached the level of similar products in the world. Due to the high accuracy of the float ball, it can ensure the sealing performance of the trap, and the whole sphere can be the sealing surface with a long service life. The unique advantage of free float type steam trap is that the built-in exhaust valve is selected, which is very sensitive and has high working quality, and can extend the overall service life of free float type steam trap. The biggest advantage of the free float trap is that it is not affected by the fluctuation of pressure, temperature and condensate flow, continuous drainage, water is drained, the minimum undercooling degree is 0ºC, which can make the heating equipment achieve the best work efficiency; Its minimum working pressure is 0.01Mpa, and the maximum back pressure rate is less than 85%.

The product is the petroleum, chemical, printing and dyeing, pharmaceutical, paper making, food and other industrial heating equipment the most ideal trap.

Nominal diameter (DN) : 15-150;

Nominal pressure (PN) : 1.6-4.0Mpa;

Maximum working pressure (PMO) : 0.2-1.6Mpa;

Maximum working temperature (TMO) : 350 ºC;

Working medium: steam condensate;

No load leakage rate is less than 3%;

And 0.5 percent supercooling

Free float type steam trap structure is simple, there is only one fine grinding stainless steel hollow float ball inside, both the float and the opening and closing parts, no vulnerable parts, long service life. When the device is just started, there is air and low temperature condensate water in the pipeline, the manual air exhaust valve can quickly eliminate non-condensing gas, the trap begins to enter the working state, the low temperature condensing water into the trap, the condensate level rises, the float rises, and the valve is opened. The device quickly raises the temperature, before the temperature in the pipeline rises to the saturation temperature, the automatic air exhaust valve has been closed; The device enters the normal operation condition, the condensate water decreases, the liquid level drops, and the float rises and falls with the liquid level to adjust the flow rate of the valve hole; When the condensate stops entering, the float approaches the valve seat with the flow of the medium, and the valve is closed. The valve seat of the free float type steam trap is always below the liquid level, forming a water seal without steam leakage.