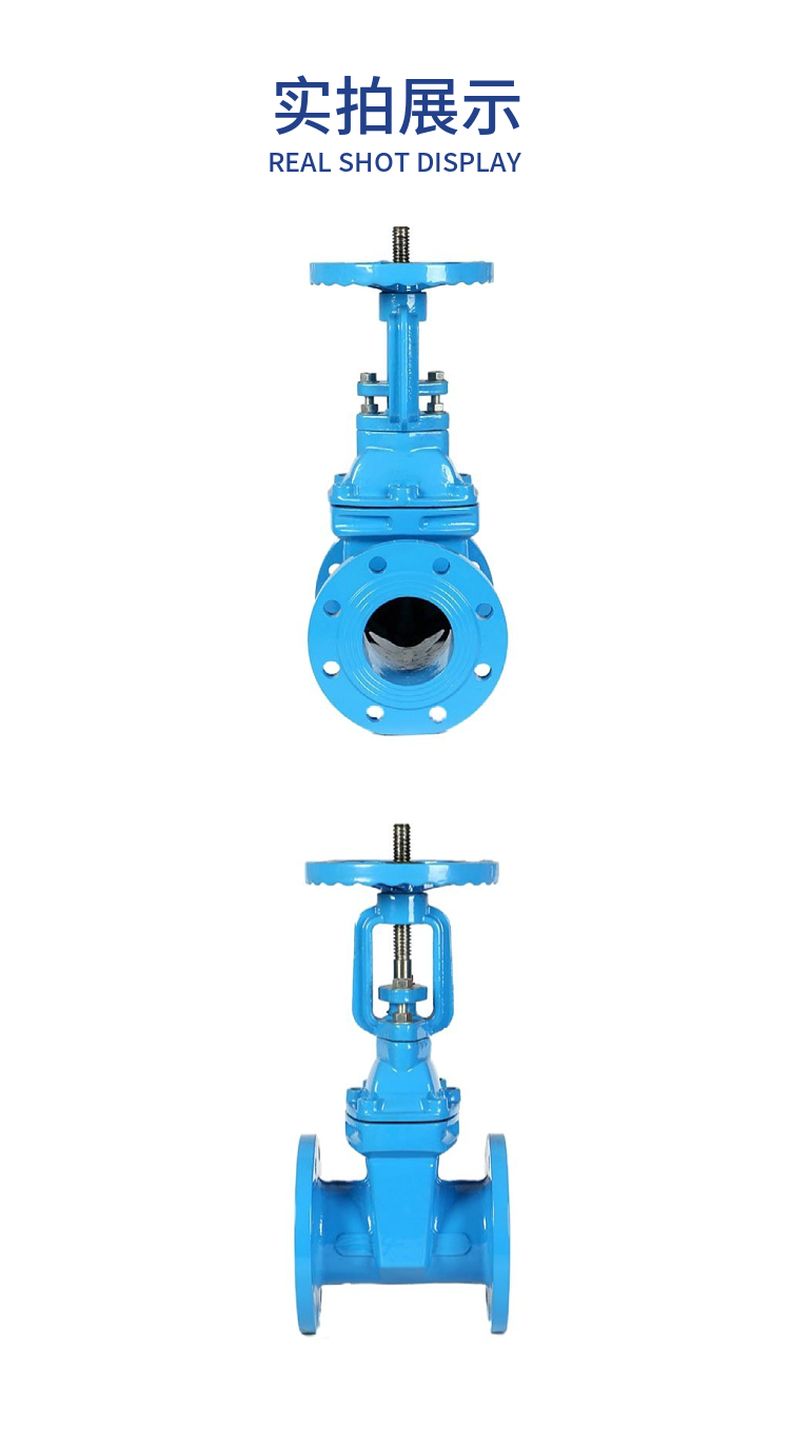

RRHX open stem elastic seat seal gate valve

Product Overview:

RRHX elastic seat seal gate valve is made of resin sand molding ductile iron, high strength, small size, weight than the traditional gate valve weight reduced by about 20% ~ 30 easy installation and maintenance. The traditional gate valve with flat base is usually concave, which increases the fluid resistance, and is easy to accumulate welding slag, stone, sand and other debris, which is not conducive to sealing and flow surface. The elastic seat sealing gate valve produced by the company adopts the flat-bottom whole basin straight through design, which is quite a pipeline, not easy to accumulate debris, to ensure reliable sealing, so that the fluid is unimpeded. Valve disc overall packaging Valve disc using high quality rubber for the overall internal and external packaging, Europe's first-class rubber vulcanization technology makes the vulcanized valve to ensure the precise geometry, and rubber and ductile ink and cast iron valve disc joint firmly, not easy to fall off and elastic memory. Precision casting valve body adopts precision sealing casting, the precise geometry makes the valve body without any processing inside to ensure the sealing of the valve. The frame of the gate is made of ductile iron, and the whole is covered with rubber, which has accurate geometric size, reliable coating, no falling off, good elastic memory and interchangeable. The inner and outer surfaces of the corrosion-resistant valve body are coated with powder epoxy resin, and the inner parts are made of stainless steel or copper alloy to prevent the corrosion and rust of the valve body, and can be used in sewage systems. And underground and other harsh environment. It is not easy to break to live in the traditional cast iron gate valve often due to foreign objects hit, collision or heavy pressure caused by fracture and other phenomena. Due to the change of the body to ductile iron, this situation can be greatly reduced. "O" type ring seal ring because the valve body does not use three "O: type ring seal design, can reduce the friction resistance when switching, greatly reduce the phenomenon of water leakage and can not stop the construction of the sealing ring. Due to the non-toxic epoxy resin coating inside the valve body, the inner and outer surfaces of the valve disc are completely covered with rubber and will not appear rusty water or corrosion phenomenon, which can be used for drinking.

Parts material:

Technical parameters:

Nominal pressure: 1.0 ~ 2.5MPa

Nominal diameter: 50 ~ 400mm

Working temperature: 0 ~ 120ºC

Applicable medium: water, oil, gas and other

flanges standard: GB/T17241.6GB9113

Test standard: GB13927API598

Appearance size: