ZSQK gas special cut-off valve

Gas special cut-off valve ZSQK

I. Product Overview:

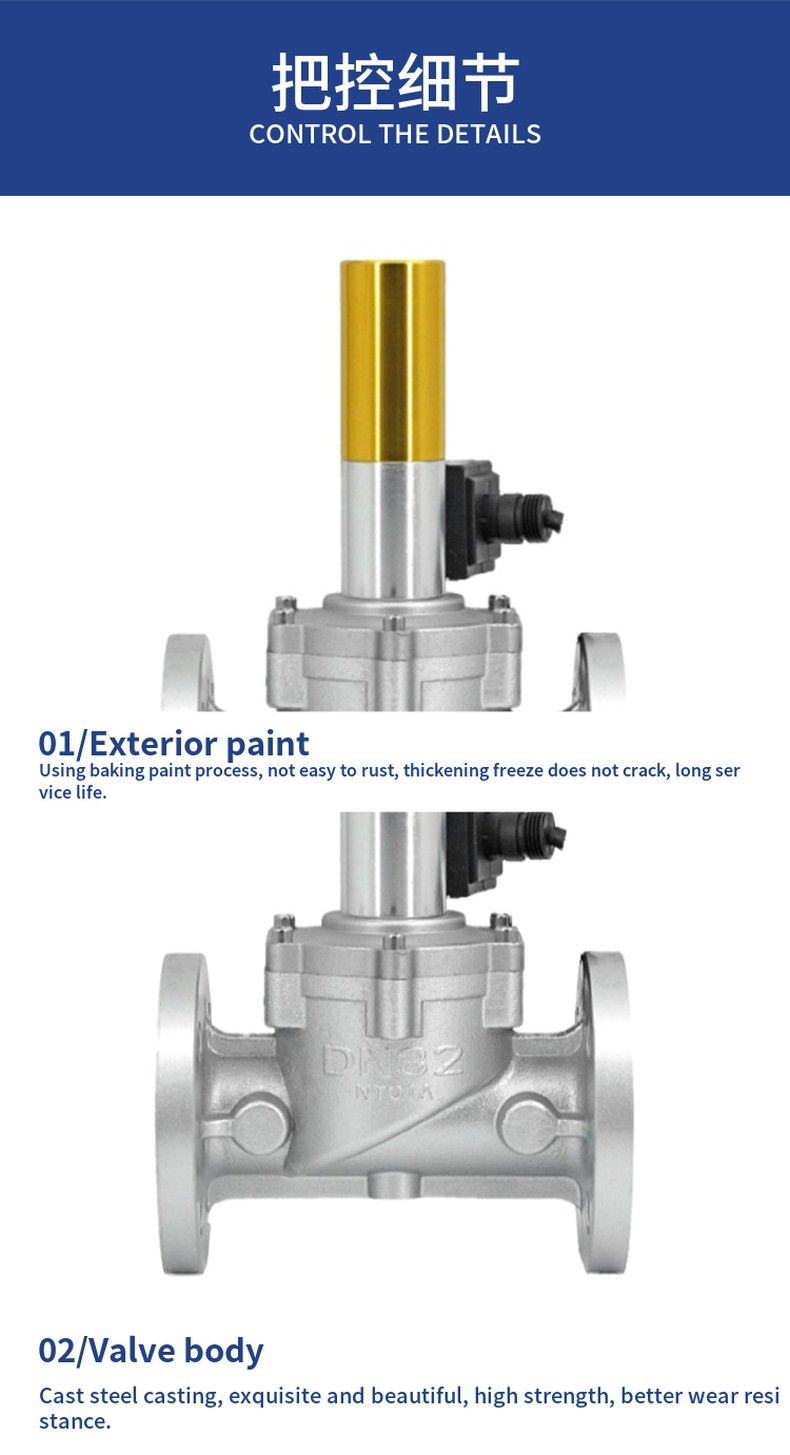

Gas special cut off valve by pneumatic multi-spring piston actuator and low flow resistance, double sealing structure of the cut off valve. The actuator has fast action speed, large thrust, self-reset function and hand operation mechanism; The valve body flow path is smooth, the flow coefficient is large, the spool seat has elastic and rigid cascade double seal. The novel structure makes this product a new type of high performance cutting valve with fast action, tight cutting off, safety and reliability.

2. Performance characteristics:

Excellent performance, complete specifications, small size, light weight. It can meet the requirements of automatic fast discharge and emergency cutting in the production process of chemical, petroleum, metallurgy and other industrial sectors. It is suitable for the safety of production process and equipment. The protection system is also suitable for general two-position control and switching operation.

Three, the working principle:

When the signal pressure is zero, due to the pre-tightening force of the spring (single action only), the spool is in the initial state (normally open or normally closed). When the actuator receives the signal pressure (0.4~0.6MPa), the spring is compressed to drive the push rod, valve body and spool to move to the limit position, so that the pneumatic cut-off valve is fully open or fully closed. To achieve the medium in the pipeline through, cut off or pipe switching control. With two-position three-way electric sample valve, the control of piston type cut-off valve is more convenient and simple.

Four, parts materials:

V. Technical parameters: