Home >> Products >> Regulating valve

I. Overview:

V230 type self-operated pressure regulating valve is A kind of energy-saving control device that does not need external A plus driving energy, relies on the pressure of the medium itself to be adjusted as the power source and the pressure change of the medium, and automatically adjusts according to the predetermined setting value. It sets detection, control and execution of many functions in a valve, and becomes an independent instrument control system. Because the product does not need external energy, the product structure is simple, easy to use, less maintenance workload and other advantages, especially suitable for urban heating, heating and no external power supply, gas supply and need to control steam pressure occasions. According to foreign reports, urban heating, heating system using this product, energy saving efficiency than before increased by 30%-40%, the effect is remarkable.

Two, regulating valve characteristics:

No additional drive energy saving automatic control system, low equipment cost, suitable for explosive environment; Simple structure, small maintenance workload; The set point can be adjusted and the range is wide, which is convenient for users to adjust continuously within the set range; Diaphragm-type actuator has higher detection accuracy and sensitive action than cylinder type mechanism; The pressure balancing mechanism is used in the valve to make the regulating valve responsive, accurate control and large allowable pressure difference.

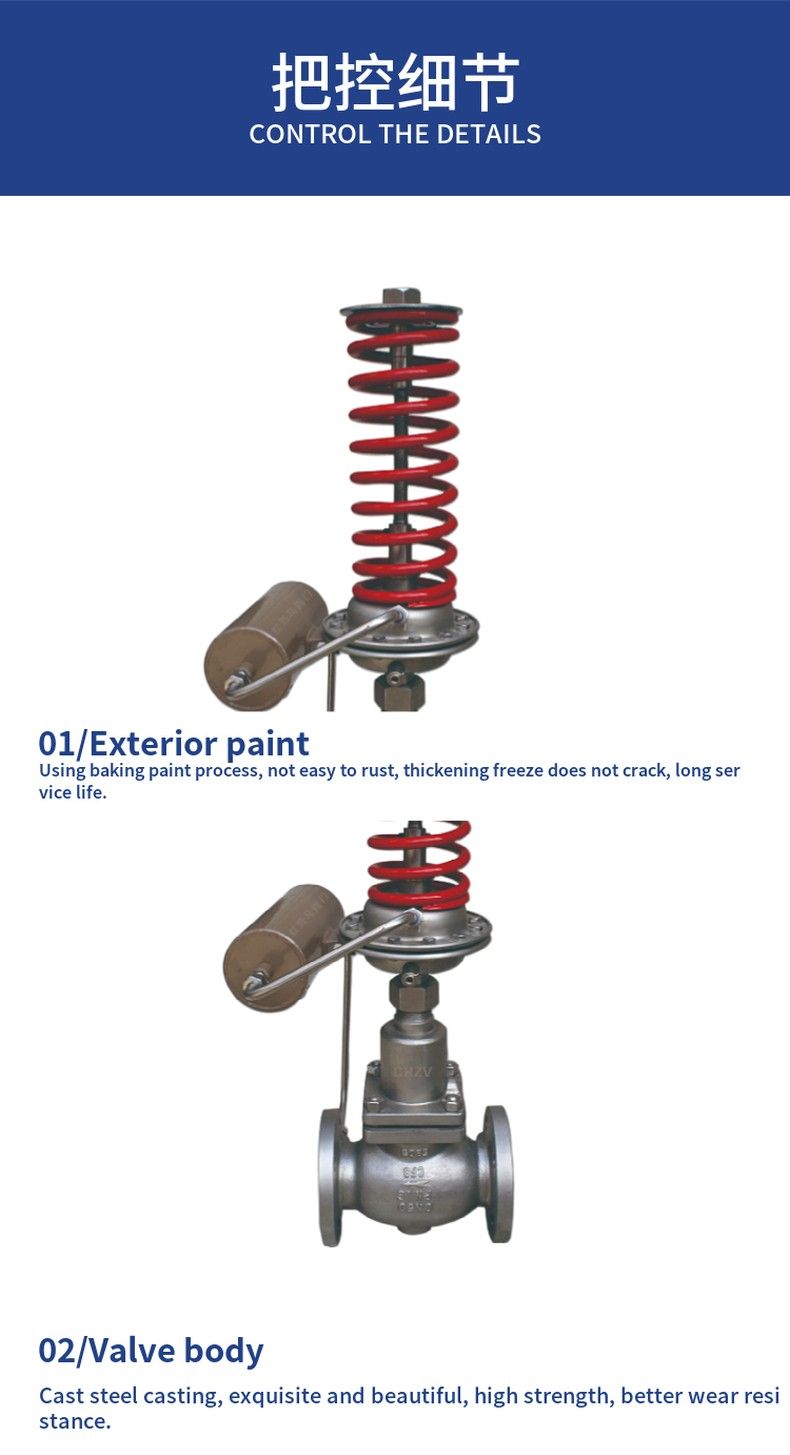

Three, the main parts of the material

Valve body: ZG230-450, ZG1Cr18 Ni9Ti, ZGCr18 Ni12Mo2Ti Sp

ool: 1Cr18 Ni9Ti, Cr18 Ni12Mo2Ti

Valve

Seat: 1Cr18 Ni9Ti, Cr18 Ni12Mo2Ti stem: 1Cr18 Ni9Ti, Cr18 Ni12Mo2Ti

Film cover: A3, A3 steel coated tetrafluoroethylene stainless steel

Filler: Nitrile, ethylene, fluorine, oil resistant rubber

Main technical parameters

| Nominal diameter DN(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| Rated flow coefficient (KV) | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | 300 | 480 | 760 | 1100 | 1750 | |

| Rated stroke (mm) | 8 | 10 | 14 | 20 | 25 | 40 | 50 | 60 | 70 | |||||

| Nominal pressure PN(Mpa) | 1.6, 4.0, 6.4 | |||||||||||||

| Pressure Adjustment Range (MP a) | 15 ~ 50 40 ~ 80 60 ~ 100 80 ~ 140 120 ~ 180 160 ~ 220 200 ~ 260 | |||||||||||||

| 240 ~ 300 280 ~ 350 330 ~ 400 380 ~ 450 430 ~ 500 480 ~ 560 540 ~ 620 | ||||||||||||||

| 600 ~ 700 680 ~ 800 780 ~ 900 880 ~ 1000 980 ~ 1500 1000 ~ 2500 | ||||||||||||||

| Flow characteristics (° C) | Quick-opening | |||||||||||||

| Adjust accuracy (%) | Plus or minus five | |||||||||||||

| Use temperature (C) | 350 or less | |||||||||||||

| Hard seal (1/h) | Single seat: ≤104 valve rated capacity (Class IV); Double seat, sleeve: ≤5×103 valve rated capacity (Class II) | |||||||||||||

| Soft seal (m1/h) | 0.15 | 0 | 0.5 | 0.6 | 0.9 | 1.7 | 4 | 6.75 | 11.1 | 16 | ||||

| Max | 10 | |||||||||||||

| Minimum | 1.25 | |||||||||||||