Baffle T filter

First, three-way reverse flow T-type filter product overview

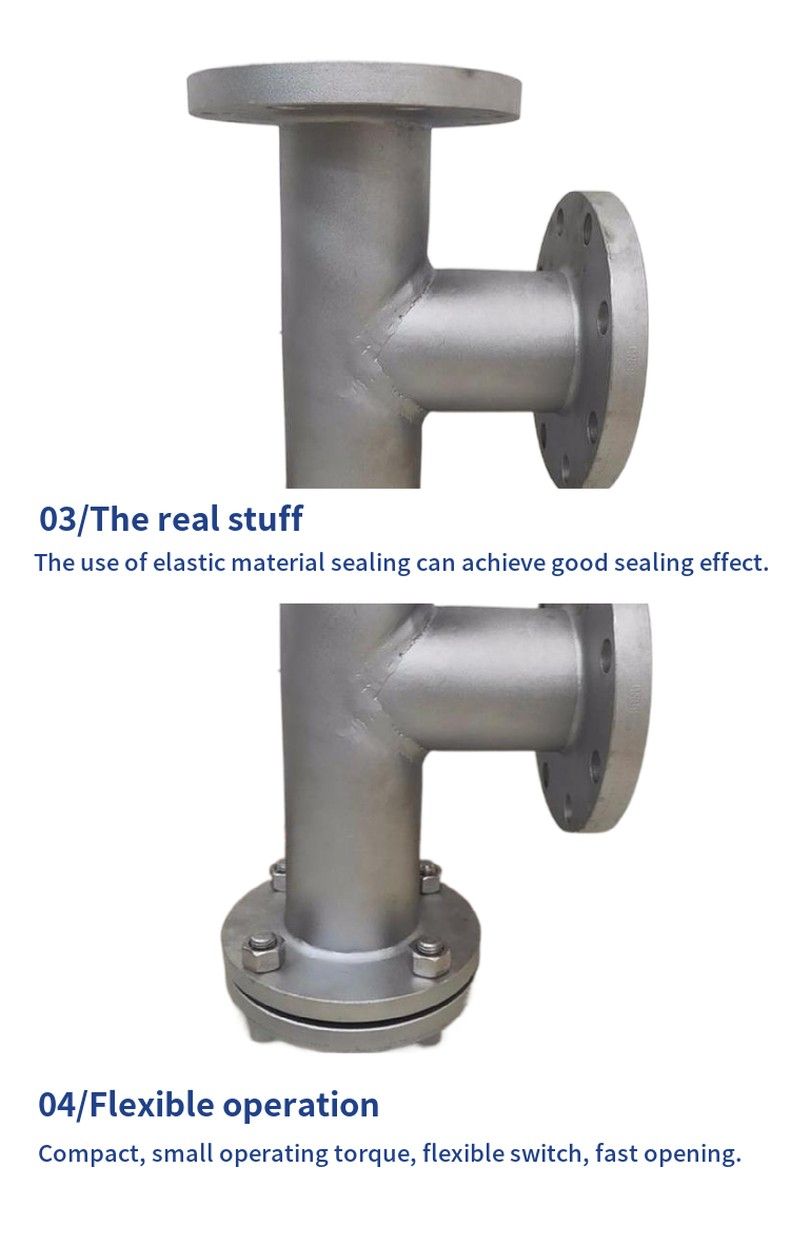

The three-way reverse folding flow filter is composed of three, flange, flange cover, discharge wire plug, filter screen filter cartridge and filter core baffle ring, etc. The flange is welded on the tube mouth of the three-way pipe through the electric welding process, the circular filter core baffle ring is placed on the straight tubular entrance of the three-way pipe fitting, one end of the circular filter core is placed on the circular baffle ring, and the other end is pressed and fixed with the flange cover. The filter element is composed of two parts of the filter cartridge and the filter screen installed outside the filter cartridge. When the fluid enters the filter cartridge with a certain specification of the filter screen, the impurities are blocked, and the clean filtrate is discharged by the filter outlet.

Tee positive baffle T type filter interface connection method can be used flange, butt welding, socket welding and internal thread, etc., which is mainly used in chemical, petrochemical, light industry and other production of liquid and gas materials, to filter its solid impurities, which is usually installed in the pump, valve, compressor inlet or flow meter before the pipe, to protect such equipment or meters. This product should be installed in the 90° flow direction change, to save elbow.

Two, three reverse flow T-type filter main parts material table

Three, three way reverse flow T-type filter main technical specification table