Home >> Products >> Check valve

H44H, H44Y type PN16~PN250,150LB-2500LB swing steel stop valve is suitable for pressure 1.6~25MPa/2.0-42.0MPa working temperature -29~+550ºC petroleum, chemical, pharmaceutical, fertilizer, power industry and other working conditions of the pipeline, The applicable medium is water, oil, steam, acidic medium and so on. It is a valve that controls the one-way flow of the medium in the pipeline, and is used to prevent the backflow of the medium in the pipeline. The check valve belongs to the automatic valve class, and the opening and closing parts are automatically opened or closed by the force of the flowing medium. The check valve is only used in the pipeline with one-way flow of the medium to prevent the backflow of the medium and prevent accidents. Mainly used in petroleum, chemical, pharmaceutical, chemical fertilizer, electric power and other pipelines.

The check valve is used in the pipeline system, and its main function is to prevent the backflow of the medium, prevent the reverse of the pump and its drive motor, and the release of the medium in the container. Check valves can also be used in piping where the pressure may rise to exceed the pressure of the main system to supply the auxiliary system.

The design and manufacture of the product meet the requirements of American national standard ANSI B16.34 and American Petroleum Institute standard API6D

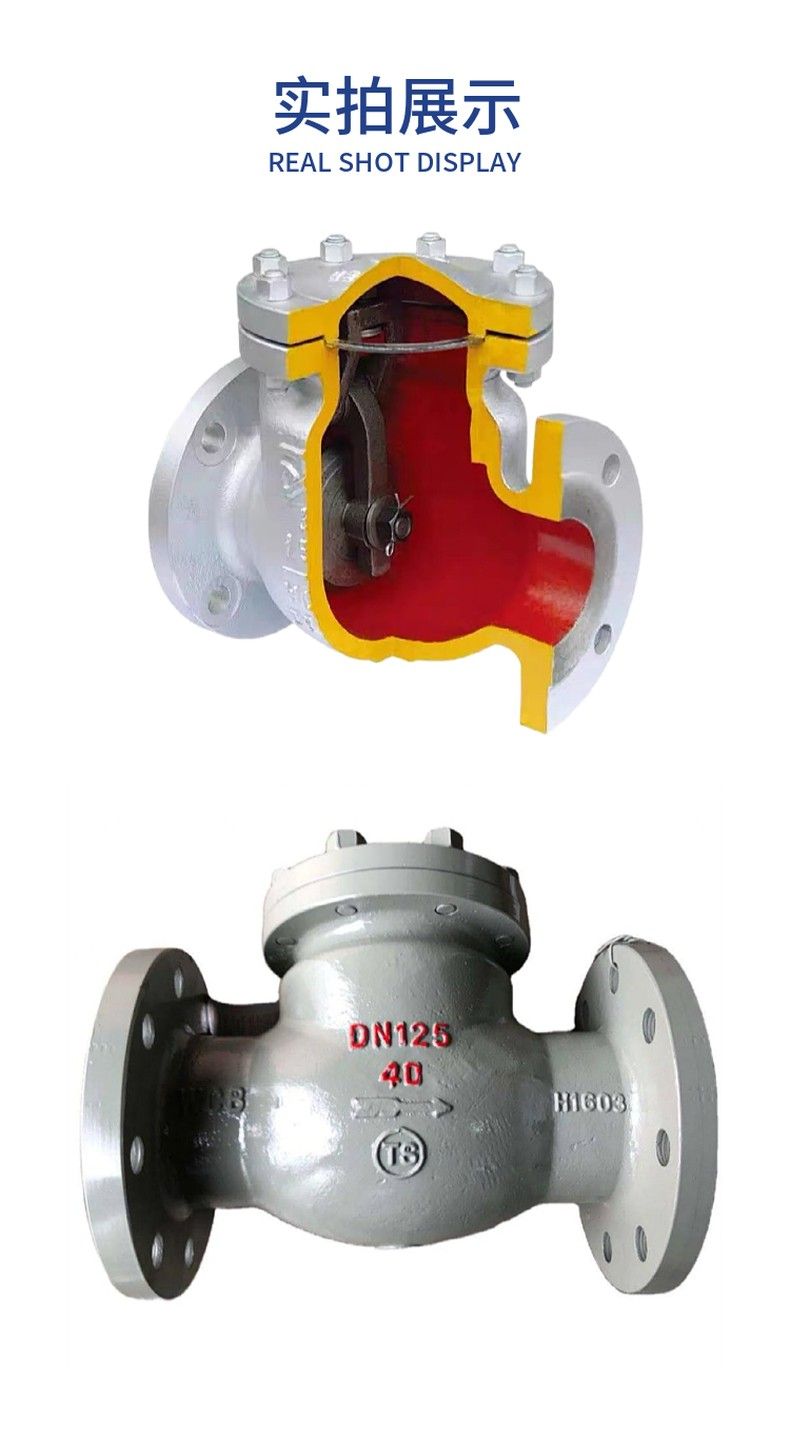

Valve pressure parts using precision casting process casting, beautiful surface quality, no sticky sand, cold insulation and other surface defects; The internal quality is stable, no porosity, sand hole, cracks and other internal defects.

Swing check valve with internal rocker arm swing structure, all the valve opening and closing parts are installed in the valve body, do not penetrate the valve body, in addition to the flange part with sealing gasket or sealing ring seal, the whole has no external leakage point, to eliminate the possibility of valve leakage.

Swing check valve rocker arm and valve disc connection using a spherical connection structure, so that the valve disc in the range of 360 ° C within a certain degree of freedom, with appropriate trace position compensation.

The sealing surface of the swing check valve seal pair is surfacing alloy steel (13Cr) or cemented carbide Stellite6, which will not wear quickly due to erosion when used in the medium with fine particles.